Not just another boring beer label.

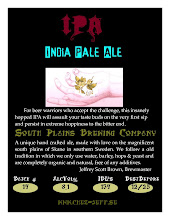

It seems I have been working on these labels forever! I feel I'm finally approaching the end.I wanted a label to reflect my beer, one that pushes the limits. I decided on my logo to be a raised fist, symbolizing rebellion against massed produced beers. First I had a front and back. Now I have a rectangular shape that wraps around the bottle. On the left side I have a description of the beer along with a description of what I do. Here's the excerpt from the Pale Ale:

A darkish yellow with copper tinge, this moderately bitter ale has a strong hoppy floral bouquet with hints of blackberry & citrus.

An artisan craft ale, brewed with purity in which we only use water, barley, hops & yeast and are free of any additives. This is a real ale, unfiltered & unpasteurized so when it is young, it is quite acidic and as it ages it gets smoother and smoother

Jeffrey Scott Brown, Brewmaster

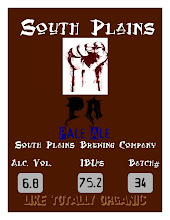

Then on the right I have some information on the beer: alcohol percent, volume, batch number and International Bittering Units, IBU's, it tell how bitter the beer is (really something for beer afectionanados), and then the bar code to track it with and the 'pant' symbol for recycling bottles.

For the fonts, I use a rock garage font on the top with the initials of the style, then put the style in a Alias font. I'm meeting today with graphics designer Joshua Alvarez at

Sveneighteen to put the final touches on. I hope to send these finished designs off to the printer soon.